Hold/jam the PV actuator plate up on the cyl closed.

Preload the PV governer spring with a .005" to .010" feeler gauge (not that critical). I used to do it by feel but this is easier and consistent.

loosen the setscrew on the bellcrank

Push/hold the governer assy fully into the case bearing, be sure its straight, and

tighten the setscrew

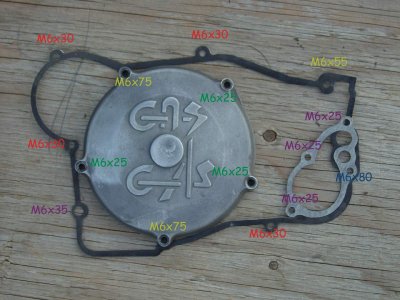

Remove feeler gauge and replace the side cover

The idea is to remove all freeplay and end up with just a VERY SLIGHT preload, so the actuator is held to the stop.

I checked mine this evening and it was pretty sloppy.

Initially, I could move the P/V actuator about 7mm before I could feel the spring tension.