GMP

Active member

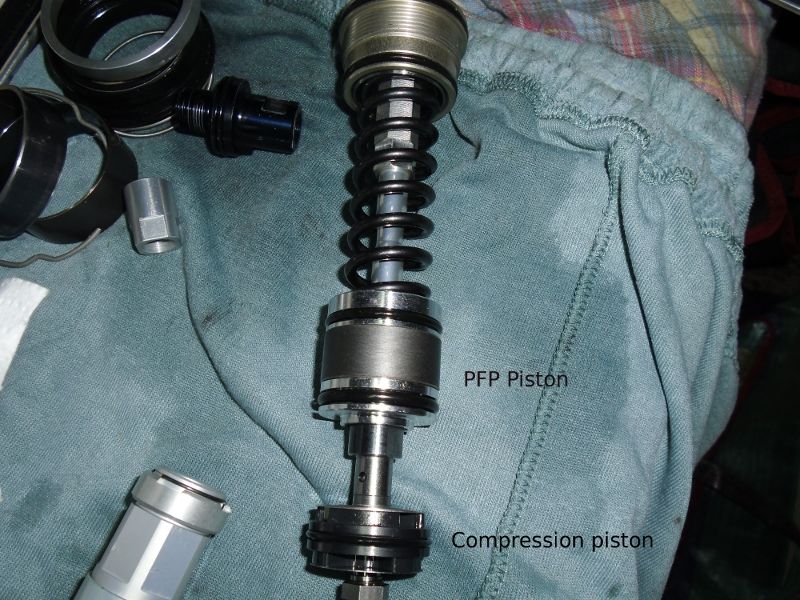

I think its the fast rebound making it extend too fast after deeper compression. Its suprisingly good on trail trash, even on uphills where there is less weight on the front end. This is where too stiff a compstack really gives you trouble and deflects. I think what I'll do is add a little HS rebound, and maybe a little less comp just to bring the adjuster in closer to midrange rather than close to full out. I'm on the fence about stiffer springs, seems OK, have to play with the PFP more first.